2020年1月1日 Exploitation and utilization of mineral resources have played a vital role in China’s rapid economic developments. Although the history of mineral processing is

2011年2月1日 Both technologies are based on pellets and lump ore as iron ore feed material. The technology used for the reduction stage is therefore the shaft furnace

15 October 2021. MELBOURNE, Australia-- (BUSINESS WIRE)-- Rio Tinto is progressing an innovative new technology to deliver low-carbon steel, using sustainable biomass in

2014年5月1日 Studies have documented the potential for the worldwide iron and steel industry to save energy by adopting commercially available energy-efficiency

2019年7月19日 Molten oxide electrolysis, where the iron ore is dissolved in a mixed oxide solvent, such as silicon oxide and calcium oxide, at ~1600 °C. The resultant molten iron

2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 1.1 for 2012 and 2018 (Australian Department of Industry, Science, Energy and

2022年1月1日 The iron ore, on the other hand, was injected into the smelt cyclone and entered the slag as pre-reduced molten oxide. By using both scrap and biomass, a

2021年7月21日 In light of this, a group of scientists has set the goal to increase self-sufficiency in iron ore. The main reason behind China's dependency on imported iron ore

2022年1月1日 23.4. Conclusions. This chapter reviews the low carbon cokemaking and BF ironmaking technologies in Japan. In cokemaking, the coal pretreatment technologies

2023年4月21日 Newsletters Term Sheet. An MIT vet wants to revolutionize the steel industry. But finding funding for big swings in climate tech isn’t easy. BY Lucy Brewster.

2011年2月1日 Both technologies are based on pellets and lump ore as iron ore feed material. The technology used for the reduction stage is therefore the shaft furnace technique. Three natural gas based processes, FINMET ( Peer, 2005 ), Circored ® ( Elmquist, Weber,Eichberger, 2002 ) and Iron Carbide can directly use fine ore by the

2014年5月1日 Studies have documented the potential for the worldwide iron and steel industry to save energy by adopting commercially available energy-efficiency technologies and measures [1], [4], [5].However, in view of the projected continuing increase in absolute steel production, future reductions (e.g., by 2030 or 2050) in absolute energy use and

2019年7月19日 Molten oxide electrolysis, where the iron ore is dissolved in a mixed oxide solvent, such as silicon oxide and calcium oxide, at ~1600 °C. The resultant molten iron collects at the bottom of the cell and is siphoned off. In MOE processes, iron ore is dissolved in a molten oxide mixture at 1823–1973 K (1550–1700 °C).

2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 1.1 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021).As shown in Fig. 1.3, China is the largest iron ore

2022年1月1日 The iron ore, on the other hand, was injected into the smelt cyclone and entered the slag as pre-reduced molten oxide. By using both scrap and biomass, a decrease of fossil carbon by 57% and an increase of hot metal production by 40% compared with a reference period operating on iron ore and coal only were achieved (Meijer et al., 2019).

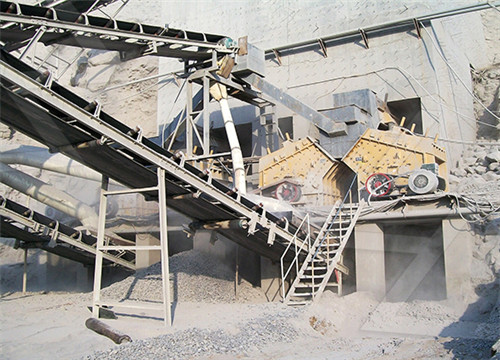

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

2020年2月8日 The iron ore industries of India are expected to bring new technologies to cater to the need of the tremendous increase in demand for quality ores for steel making. With the high-grade ores depleting very fast, the focus is on the beneficiation of low-grade resources. However, most of these ores do not respond well to the conventional

2023年4月21日 Newsletters Term Sheet. An MIT vet wants to revolutionize the steel industry. But finding funding for big swings in climate tech isn’t easy. BY Lucy Brewster. April 21, 2023, 3:54 AM PDT

2017年12月20日 Iron Ore Agglomeration Technologies. Until the 1950s of the last century, the oxidized iron ores that were loaded into the blast furnace had granulometries within 10 and 120 mm. However, the depletion of high-grade iron ore sources has made necessary the utilization of concentration processes with the purpose of enriching the iron ore.

enhance efficiency of iron ore magnetic separation by applying ultrasonic technologies. Thus, it is required to combine research results in the following directions: theoretical and practical research into iron ore magnetic separation; methods and means of operative control over physical-mechanical and chemical-

2014年5月1日 Studies have documented the potential for the worldwide iron and steel industry to save energy by adopting commercially available energy-efficiency technologies and measures [1], [4], [5].However, in view of the projected continuing increase in absolute steel production, future reductions (e.g., by 2030 or 2050) in absolute energy use and

2022年2月10日 The technology can also be applied for the direct reduction of iron ore to eliminate the cost and energy-intensive agglomeration step of iron ore fines in the form of sintering or pelletizing. The Circored Process. The generic Circored process is based on the reduction behavior of iron ore, shown in Fig. 1.

2022年1月1日 The iron ore, on the other hand, was injected into the smelt cyclone and entered the slag as pre-reduced molten oxide. By using both scrap and biomass, a decrease of fossil carbon by 57% and an increase of hot metal production by 40% compared with a reference period operating on iron ore and coal only were achieved (Meijer et al., 2019).

2019年7月19日 First of all, Fig. 10.3 shows that for a G factor of 4 A.cm1, which corresponds to todays’ Hall-Heroult cell technology, a reduction in CO 2 emissions can be obtained for a conductivity slightly above 2 Scm −1 whatever the mode of electricity generation. A combination of an advanced electrolysis cell with a low G factor and

2022年1月1日 Turning to iron ore exports and imports, the tonnages are summarized in Table 1.1 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021).As shown in Fig. 1.3, China is the largest iron ore

2022年1月1日 Most of the high-grade hematite iron ores are typically subjected to simple dry processes of crushing and classification to meet the size specifications required for direct shipping ore (DSO). This involves multistages of crushing and screening to obtain lump (−31.5 + 6.3 mm) and fines (approximately −6.3 mm) products.

2021年7月21日 In light of this, a group of scientists has set the goal to increase self-sufficiency in iron ore. The main reason behind China's dependency on imported iron ore is that the country's iron ore is relatively low-grade and expensive to process. Ever since 35-year-old Sun Yongsheng acquired a doctorate in mining science six years ago, he has

2020年2月9日 Fe 2 O 3 pur e Percentage of pure iron ore in the ir on ore stream (assumed to be 0.95) FeO ra tio Ratio of molecular weight of iron contained in iron oxide (0.7) EL pel heater Electrical energy

2023年4月21日 Newsletters Term Sheet. An MIT vet wants to revolutionize the steel industry. But finding funding for big swings in climate tech isn’t easy. BY Lucy Brewster. April 21, 2023, 3:54 AM PDT

2017年12月20日 Iron Ore Agglomeration Technologies. Until the 1950s of the last century, the oxidized iron ores that were loaded into the blast furnace had granulometries within 10 and 120 mm. However, the depletion of high-grade iron ore sources has made necessary the utilization of concentration processes with the purpose of enriching the iron ore.