2020年7月28日 The extraction process routes to recover high purity of platinum group elements are also reviewed. The classification briefly describes the different types of ore deposits. The mineralogical analysis gives a general idea about the distribution and

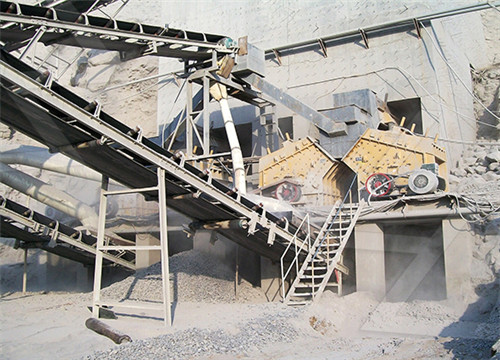

Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in

2018年2月21日 About 80% of the worlds’ reserves for platinum group metals (PGMs) are in South Africa’s Bushveld Igneous Complex.

According to the results, the green, blue, and grey WF of the studied mine are 52.04, 988.83, and 69.78 m3/tonne of copper concentrate, respectively. After the installation of a passive effluent

2023年4月25日 Sperrylite is a platinum arsenide mineral. The first documented discovery of platinum was by the Spaniards in the 1500s, in the alluvial gold mines of the Río Pinto,

Nov 19, 2021Within an ore body, valuable minerals are surrounded by gangue and it is the primary function of mineral processing, to liberate and concentrate those valuable

Platinum Element information, properties and uses Platinum is used extensively for jewellery Its main use, however, is in catalytic converters for cars, trucks and buses This accounts

floatation process touch screen polish mashine; gold mining equipment in india made by henan supplier; function of form wet ball mill; magnetic separator plant m achinery

main functions of a platinum mineral processor. 2x Steel, 1x Platinum Mineral Processor Alloy both minerals in the mineral processor osmium carbide plasteel 5x plasteel, 3x

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

2019年3月30日 The main focus will be on platinum-group minerals (PGM) and phases rich in the platinum-group elements (PGE). Our Special Issue will cover a broad range of relevant topics of interest, such as: The

2018年3月22日 Once the PGM-containing ore has been mined, concentrated and smelted (removal of Fe and Pb), the refining process occurs in two main phases: (1) base metal refining, where Ni, Co and Cu are

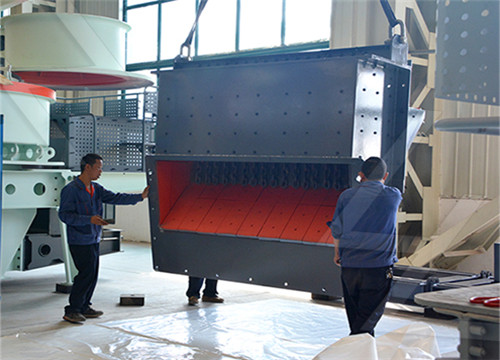

2013年4月1日 The valuable minerals in UG2 have significantly smaller average grain sizes and require fine grinds to optimally liberate the valuable components (Rule, 2008). Cramer (2001) anticipated the future of the PGM processing industries would require further development of the processes to address the encountered technical challenges.

2020年11月16日 This stone reviews the PGMs recovery from waste catalysts using a metals smelting-collection process, which belongs to the main pyrometallurgical process, in the presence of various metal collectors, such as lead, copper, iron, matte, print circuit board (PCB) or reactive metals of calcium and magnesium. Mineral ProcessingExtractive

Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position. These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methods.

2019年8月16日 Mining, mineral processing and metal extraction are undergoing a profound transformation as a result of two revolutions in the making—one, advances in digital technologies and the other, availability of electricity from renewable energy sources at affordable prices. The demand for new metals and materials has also arisen

According to the results, the green, blue, and grey WF of the studied mine are 52.04, 988.83, and 69.78 m3/tonne of copper concentrate, respectively. After the installation of a passive effluent

floatation process touch screen polish mashine; gold mining equipment in india made by henan supplier; function of form wet ball mill; magnetic separator plant m achinery manufacturers; broyeur agrave boulets ball mill m; 400 ton per day alluvial gold trommel made in china; how alluvial gold mining how aluminium is made; technical machine

main functions of a platinum mineral processor. 2x Steel, 1x Platinum Mineral Processor Alloy both minerals in the mineral processor osmium carbide plasteel 5x plasteel, 3x osmium Mineral Processor Use an ID card to open the and turn the main beaker on. Swipe card to unlock ; Remove the power cell. Screwdriver the assembly. Lift the

Lorem ipsum dolor Address: No.169, Science (Kexue) Avenue, Tel: 0086-371- Email: [email protected]

2018年3月22日 Once the PGM-containing ore has been mined, concentrated and smelted (removal of Fe and Pb), the refining process occurs in two main phases: (1) base metal refining, where Ni, Co and Cu are

2019年3月30日 The main focus will be on platinum-group minerals (PGM) and phases rich in the platinum-group elements (PGE). Our Special Issue will cover a broad range of relevant topics of interest, such as: The

2018年1月6日 Devendra Deo Pathak. Platinum Group Metals (PGMs) play a significant role in the manufacturing of catalysts, super alloys, electronics, space materials, biomedical equipments, jewellery, etc. due

Mineral processing, mineral beneficiation, or upgradation involves handling three primary types of ROM material, which have been blasted, fragmented, and brought out from an in situ position. These materials can be used directly or by simple or complex processing and even by applying extractive metallurgy like hydrometallurgical or pyrometallurgical methods.

2020年11月16日 This stone reviews the PGMs recovery from waste catalysts using a metals smelting-collection process, which belongs to the main pyrometallurgical process, in the presence of various metal collectors, such as lead, copper, iron, matte, print circuit board (PCB) or reactive metals of calcium and magnesium. Mineral ProcessingExtractive

2021年9月10日 The main lines of research that would bring into processing non-conventional metal sources are sub-stantiated. Analysis of new processing and metallurgical methods of PGM recovery from non-conventional and industrial raw materials is conducted; the review of existing processing technologies for platinum-bearing raw materials is

2023年4月25日 Sperrylite is a platinum arsenide mineral. The first documented discovery of platinum was by the Spaniards in the 1500s, in the alluvial gold mines of the Río Pinto, Colombia. They called it platina del Pinto, from platina, which means “little silver,” thinking that it was an impure ore of silver. It was not recognized as a distinct metal

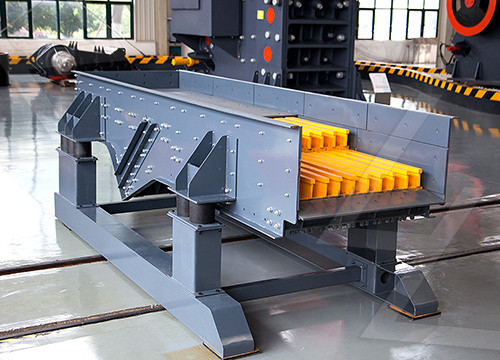

2015年8月1日 This article focuses on quantifying the benefits of process control systems in the mineral processing industry. The benefits sought in the mineral processing industry are the same sought in other commodity industry, namely throughput gain, process stability, energy consumption reduction, and increased yield. A survey by Bauer and Craig (2007

2023年3月23日 platinum (Pt), chemical element, the best known and most widely used of the six platinum metals of Groups 8–10, Periods 5 and 6, of the periodic table. A very heavy, precious, silver-white metal, platinum is soft and ductile and has a high melting point and good resistance to corrosion and chemical attack. For example, its surface remains