2016年4月1日 Then, the filtration surfaces are cleaned using mechanical shakers, reverse air, or pulse jet [66, 67]. For enhancement of the bag

2017年5月9日 Most plants are investing in CEM systems in order to burn waste, obtain ISO 14000 and 18001 certification to protect operator's life. In this work, our approach

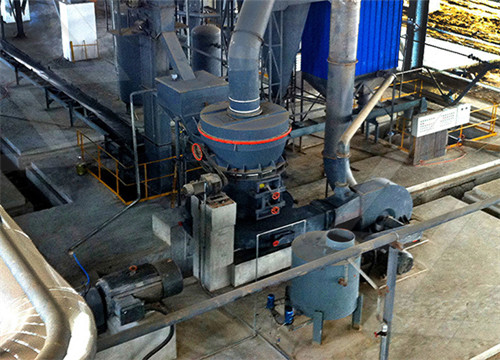

2021年8月11日 The working principle of the bag filter in cement plant is: dust-containing gas enters the middle and lower boxes from the air inlet of the dust collector, and enters the upper box through the filter bag. Due to

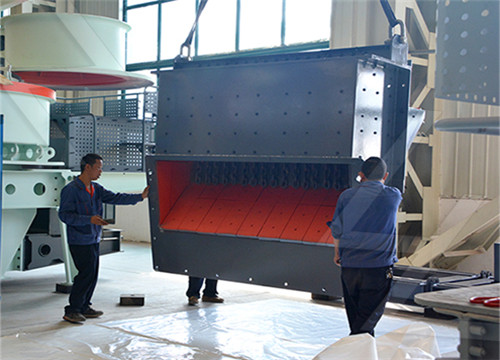

Bag Filter Maintenance Notes. Bags in a bag filter. Before maintaining or repairing the bag filter, its power supply and air source must be cut off, and the airbag should be under normal pressure. During the maintenance

Now let me introduce the application characteristics of bag filter collectors in the cement industry. 1. Adapt to the requirements of high concentration dust in the cement industry.

Pulse Jet Bag Filter Working Principle. The pulse jet bag filter and blowback bag filter are both fabric filters and use compressed air to clean the dust, but their principles are

2023年4月3日 The working principle of the bag filter in cement plant is: dust-containing gas enters the middle and lower boxes from the air inlet of the dust collector, and enters the

Liquid Filtration. J.F. RICHARDSON, J.R. BACKHURST, in Chemical Engineering (Fifth Edition), Volume 2, 2002 7.4.3. Bag filters. Bag filters have now been almost entirely

Table 1: Comparison between three types of bag filters regarding as time of operation and efficiency of dust filtration. Operation time of Polyester 550 g m -2 was 328 days. Data showed that non-woven Polyester filters 550 g

2017年5月9日 Most plants are investing in CEM systems in order to burn waste, obtain ISO 14000 and 18001 certification to protect operator's life. In this work, our approach describes development of a novel internet and fuzzy-based CEM system (IFCEMS). This system contains operator's stations for the bag filter's automation system and monitored using

2018年3月1日 By considering the drawbacks, the EP system was replaced by a bag filter (BF) system. The BF allows higher temperature of gas inlet and it has higher dust removal efficiency. In this study, the

2021年8月28日 Distribution of dust emissions at bag filters in the cement mill section no.1 (mill filter — point A and separator filter — point B, Figure 1) of the analyzed cement plant.

2021年9月15日 Bag filter is a combination of fiber filtration, or membrane filtration and dust layer filtration, and its dust removal mechanism is the result of the combined effect of sieving, inertial collision, hooking, diffusion, gravitational sedimentation and static electricity. (1) Sieving effect: When the particle diameter of dust is larger than the

Pulse Jet Bag Filter Working Principle. The pulse jet bag filter and blowback bag filter are both fabric filters and use compressed air to clean the dust, but their principles are obviously different. Taking a 2.5m diameter shaft kiln as an example, using the bag filter can recover 3103 tons of cement dust a year, creating a value of about

Industrial Filtration for the Cement Industry Cement consists of very hard and abrasive dust particles. Being very abrasive, this dust type rapidly wears out filter bags. To ensure the filters do not fail, frequent filter bag

Whether you’re working on your first liquid filter bag system or refurbishing an existing system, the following pages provide the information necessary for understanding liquid filter bag systems and their operation. 3.0

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Bag Filters in Boiler. Bag Filters are air pollution controlling industrial equipment, used prominently in a Steam Boiler House Assembly. It is used to control the levels of sulfur dioxide and others. The Bag Filter is a dust

2023年4月13日 During cement production process, there is a lot of dust and gas emissions outwardly, there are many different filter bags can be chosen for meet varied working condition. Capacity: 2000 pcs per day.

2017年5月9日 Most plants are investing in CEM systems in order to burn waste, obtain ISO 14000 and 18001 certification to protect operator's life. In this work, our approach describes development of a novel internet and fuzzy-based CEM system (IFCEMS). This system contains operator's stations for the bag filter's automation system and monitored using

2018年3月1日 By considering the drawbacks, the EP system was replaced by a bag filter (BF) system. The BF allows higher temperature of gas inlet and it has higher dust removal efficiency. In this study, the

Pulse Jet Bag Filter Working Principle. The pulse jet bag filter and blowback bag filter are both fabric filters and use compressed air to clean the dust, but their principles are obviously different. Taking a 2.5m diameter shaft kiln as an example, using the bag filter can recover 3103 tons of cement dust a year, creating a value of about

Contribute to chengxinjia/sbm development by creating an account on GitHub.

Incident: a road tanker was blowing cement under pressure into a 25-tonne silo at a concrete batching plant. The bag filter unit on top of the silo became blocked because of overfilling. Air pressure in the silo built up and the relief device failed to operate. All automated systems can work 24 hours a day. Euromec’s grabs can be used in

2021年11月27日 Cements Ground in the Vertical Roller Mill Fulfil the Quality Requirements of...

Bag Filters in Boiler. Bag Filters are air pollution controlling industrial equipment, used prominently in a Steam Boiler House Assembly. It is used to control the levels of sulfur dioxide and others. The Bag Filter is a dust

2023年4月13日 During cement production process, there is a lot of dust and gas emissions outwardly, there are many different filter bags can be chosen for meet varied working condition. Capacity: 2000 pcs per day.

2023年4月18日 A baghouse is a dust-collecting mechanism that uses tubes, envelopes, or cartridges to remove, capture, and separate dirt, particulate matter, and dust from the air of a manufacturing or processing facility. The main components of a baghouse are the media or bags used to filter particles from the air as it passes through the system.

Baghouses utilize fabric filter bags or pleated filters arranged in rows and mounted vertically in a sheet metal housing. They are designed to receive dusty gas from fugitive or process sources, capture the particulates, and exhaust clean air. Typically via an induced draft blower, the dusty gas stream is drawn into the baghouse through a duct