Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation,

2023年3月1日 FEECO is an industry leader in custom agglomeration equipment and process solutions. We can provide individual pieces of equipment, as well as complete

Sinter is the primary feed material for making iron in a blast furnace. According to the U.S. Environmental Protection Agency, the sintering process converts fine-sized raw

The beneficiation process should be as efficient and simple as possible, such as the development of energy-saving equipment, and the best

2023年4月15日 The former mainly selects magnetite ore, and the latter is mainly used for sorting hematite, mixed iron ore and weak magnetic ore. 6.2 Magnetic separation

MineralOre Processing. Ore processing is a chain of processing applications which treats run of mine to firstly high-grade concentrate (concentration of ores) and then to the pure

Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

2 之 Our sorting equipment or mineral processing equipment, specially developed for mining applications, enables processes to be better controlled, and through ore sorting even ores that were previously not

2023年4月26日 Mixer. Grinding Steel Ball. Trommel Screen. High Efficiency Concentrator. Disk Granulator. High Frequency Screen. Pendulum Feeder. After stone crushing

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials

Sinter is the primary feed material for making iron in a blast furnace. Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the chemistry and then igniting it at 1200°C in a continuous belt-fed furnace. Sinter feed composition control is important because the various sinter feed

2023年4月15日 The former mainly selects magnetite ore, and the latter is mainly used for sorting hematite, mixed iron ore and weak magnetic ore. 6.2 Magnetic separation cation reverse flotation process The grade of iron concentrate increased from 65.55% to 38.89%, the silica content decreased from 8.31% to 3.90%, and the iron recovery rate was over

Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all

Iron Ore Mining Equipment Achieve a Higher Fe Content. Efficiently remove silica, alumina, clay, and other contaminants from your feed material to increase the Fe value in the final ore. Our iron ore beneficiation projects have increased the Fe content from 43% in the feed to above 60% in the final iron ore product, ensuring increased

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red;

JXSC mining machinery conducted design and research and supplied equipment for about 200+ ore processing plant, completed 1000+ ore mining and processing plants projects in 40+ countries and regions. We are dedicated to providing you with one-stop and customized mineral extraction process! We are committed to on offering services for the ore mining

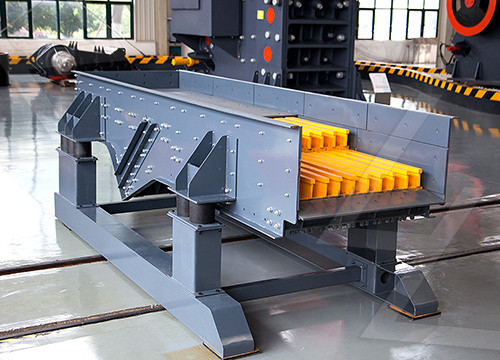

2023年2月22日 Iron Ore Mining Process. 1. Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will be transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for

2022年8月17日 Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step, from large pieces of raw iron ore (about 500mm) to millimeter-level fine materials. Iron ore crushing process. In the iron ore crushing process, the feeder, first crushing, secondary crushing, screening, fine crushing and dry selection are

Reliable equipment to handle the large volumes required in your iron ore mine. For the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops. Automation, digitalization and use of the latest technology in everything from bulk materials

Sinter is the primary feed material for making iron in a blast furnace. Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the chemistry and then igniting it at 1200°C in a continuous belt-fed furnace. Sinter feed composition control is important because the various sinter feed

Driven by a global team of process engineers and metallurgical specialists, Multotec designs, builds, manufactures, installs and maintains equipment throughout the entire value chain of mineral processing plants across all

Iron Ore Mining Equipment Achieve a Higher Fe Content. Efficiently remove silica, alumina, clay, and other contaminants from your feed material to increase the Fe value in the final ore. Our iron ore beneficiation projects have increased the Fe content from 43% in the feed to above 60% in the final iron ore product, ensuring increased

Iron Ore Process Equipment 29,952 products found from 768 Iron Ore Process Equipment manufacturerssuppliers. Product List ; Supplier List; View:

2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries. However, the content of iron in ore deposits has deteriorated and low

Iron ore; Minor metals; Non-Metallic Mineral Mining and Quarrying; Precious Metals and Minerals Engineered Solutions and Equipment for Wet Mechanical Processing and Process Water Management. Ore, Coal, Lignite and Slag. ANDRITZ SEPARATION. Solid and Liquid Separation and Refining Solutions for Beneficiation. Appropriate Process

JXSC mining machinery conducted design and research and supplied equipment for about 200+ ore processing plant, completed 1000+ ore mining and processing plants projects in 40+ countries and regions. We are dedicated to providing you with one-stop and customized mineral extraction process! We are committed to on offering services for the ore mining

2023年2月20日 iron ore mines Iron ore mining requires a range of equipment to extract the ore and prepare it for further processing. The exact equipment required varies depending on the type of mining operation

2023年2月22日 Iron Ore Mining Process. 1. Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first crushing, the material will be transferred to cone crusher by belt conveyor for secondary crushing; the crushed iron ore stone will then transferred to vibrating screen for